Pipe Lining for Repair of Drain And Sewer Pipes

Whenever you are managing slow drains, leaks and odors, have the team at Pipe Restoration

Solutions fix your pipe from within! We give drain and sewer pipe lining, a proven alternative

method for sewer fix that is quicker, more affordable, and significantly less invasive than

traditional pipe replacement.

Drain And Sewer Pipe Lining From Pipe Restoration Solutions

Very few individuals give a lot of consideration to the pipes in their walls and floors, that is until there is an issue. As slow drains, blockages, leaks, foul odors, and different issues can be frustrating, you will need expert pipe repair agents to take care of business. At PRS, we encourage our clients to act immediately before things get worse. Reach out to our team immediately so we can have your drain system working like new again – faster, with less issue, no property damage, and for undeniably less cost than traditional pipe replacement.

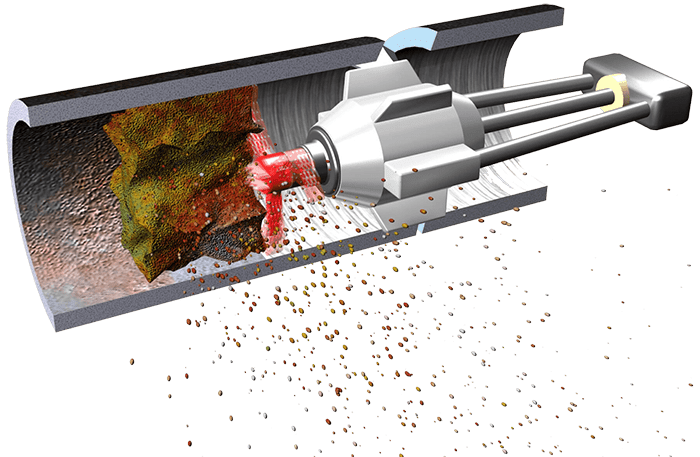

Cleaning

Blocked, damaged, or root-intruded pipes are cleaned with our hydrojetter or mechanical cleaning tools to get the pipe back to its original shape and diameter.

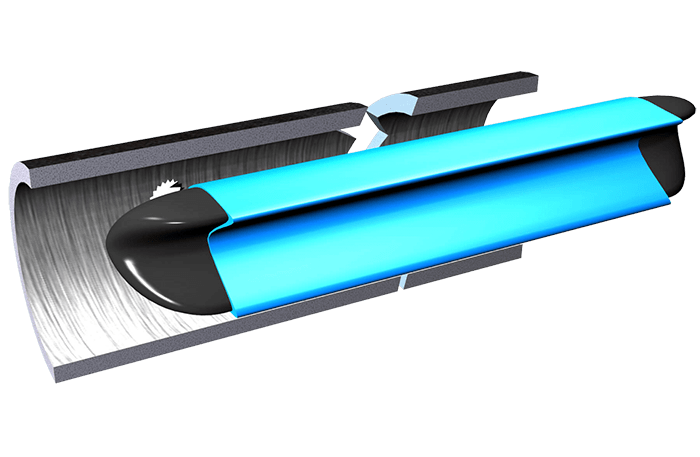

Installation

An epoxy-saturated liner is pulled into place through existing access points such as a toilet or a roof vent and an internal rubber bladder is inflated, pressing the epoxy saturated liner against the existing pipe wall.

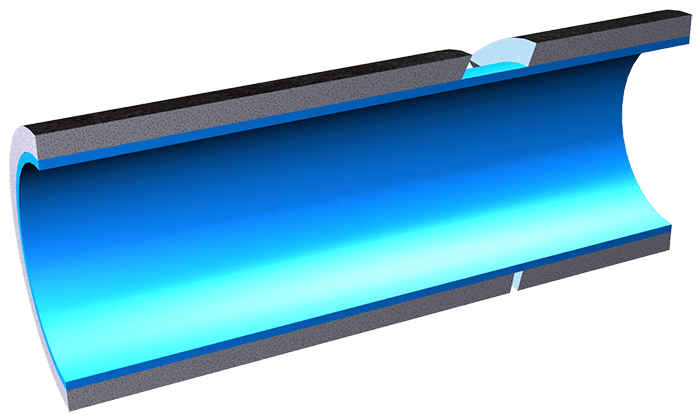

Restored Pipe

The epoxy cures in a few short hours, then the bladder is deflated and removed, leaving behind a new, clean, and seamless “pipe within a pipe.”

The Process Of Drain And Sewer Pipe Lining

Pipe lining deals with all significant kinds of piping materials. First, we will conduct a drain or sewer inspection with the use of a high-resolution camera so we can check for blocked or corroded pipes. Once found, we utilize one of a few cleaning processes, depending upon the issue. Regularly, our team will utilize hydro jetting or a mechanical tool to eliminate any dirt, grease, and obstructions, ensuring that the original pipe is as clean as possible.

Next, we rely on our cured-in place pipe lining method wherein we insert a textile liner into the damaged pipe. The liner is impregnated utilizing a liquid resin, an epoxy base, as well as a hardener. Afterwards, the bladder expands the pipe liner, squeezing the epoxy against within the line walls. When it fixes, the bladder is emptied leaving you with a spotless and consistent “pipe-inside a-pipe.”

Issues That Require Drain And Sewer Pipe Lining

When you notice that you have been dealing with reoccurring blockages, gurgling drains, sudden breaks, and foul sewer smells, your sewer system might have been compromised. While we suggest an intensive cleaning after we lead a camera inspection, these side effects may indicate a far worse underlying issue. These are warnings that will require the immediate attention from Pipe Restoration Solutions.

We will evaluate the findings of the camera inspection, and in the event that the issues continue to happen, it could be a broken pipe or skewed joint. These can imply that you do permanent sewer pipe repair arrangement. While you can choose to replace all your pipes by tearing out walls, ceilings, and landscaping, you will be left with the dust, debris, and headaches that go along with it. What we offer at PRS is a specialist group that will line the current pipes from within with safe and proven technology. We will reestablish the flow and seal the pipe against leaks and roots. Through this minimally invasive method of sewer crack repair, we can line drain and sewer pipes from 2” all the way up to 36”, both inside and outside your house or building.

The Benefits Of Drain And Sewer Pipe Lining for Pipe Repair

Sewer and drainpipe lining is useful in countless ways, as this strategy for trenchless sewer repair is less problematic, quite often more reasonable, commonly quicker, and endures similarly as long as conventional pipe replacement.

Pipe lining limits damage to floors, walls, and landscaping areas since we embed the coating through existing cleanouts or other sewer passages. If the sewer pipe is under cement or asphalt, there could be a possibility of using a drill to get to the pipe as this lining innovation slides directly into the current pipe.

This strategy for channel and sewer fix is more practical than pipe replacement since it regularly costs undeniably less, particularly since there is almost no redesign or fix costs related with it. We ensure minimal exterior digging, which reduces clean-up costs and keeps overall labor costs down. Many times we see statements from pipe replacement companies that indicate that pipe lining costs them half what the pipe replacement would.

Without the need to dig or invest too much time fixing walls, floors, and roofs, pipe lining saves huge time compared with pipe replacement. Moreover, lining lessens the possibility of holes or blockages as well as any inconvenience for you and your community because our team solves the problem in the long term.

At Pipe Restoration Solutions, we have been doing pipe lining for quite a long time. Our pipe lining technologies have a life expectancy of about 50-100 years, which is about the same as conventional pipe replacement. That means you get the ease and speed that comes with pipe lining, without sacrificing longevity – all for a more reasonable price.

Ready to start your project?

Our experienced technicians will knock out your problem quickly!

We have offices in California and Florida but offer service nationwide. We have local crews in all areas! Reach out for us to meet all your pipe restoration needs.